STORY of

TECHNOLOGYfrom DHF

03

T-head construction method

A new technology driving construction of modern Japan

Buildings, apartments, and other concrete structures rely on steel reinforcement bars (rebar). The DHF T-head construction method is a revolutionary construction technique that greatly improves the efficiency of steel bar-reinforced structures. By changing the traditional hook ends of rebar into a “T” shape, the traditionally complex process of positioning rebar can be done quickly and efficiently, and the strength added to the concrete is likewise increased. While maintaining and even improving upon the performance of traditional structures, DHF T-head construction method vastly improves the ease of construction.

The high level of DHF technical abilities that are a great source of pride for the company, plus the will at the root of all DHF employees to want to help people at constructions sites who are at a loss as to the best way to proceed, are given concrete form in this symbolic story. This technology was ultimately recognized by the Ministry of Land, Infrastructure, Transport and Tourism, and was a received the Infrastructure Technology Development Award by the Ministry. It was truly born from a “Columbus's egg” type intuition.

The intuition of the salesman that didn't sell our equipment

Surprisingly, the idea behind the T-head construction method did not come from any of our engineering divisions, but actually from the Equipment Business Division, which was tasked with selling customers high-frequency induction heating equipment. Before the advent of the T-head construction method, the conventional method was to form the end of a bar into a U-shape and set it in the concrete as a hook. This method, however, had many issues: It made construction plans more complex and decreased construction efficiency; it resulted in insufficient complementary strength, and caused problems in terms of cost and construction time. As an alternative method, we discovered a way to take rebar, and small steel plates, welding them together and create a stronger form for reinforcing concrete bars.

One day a general construction contractor asked our Equipment Business Division, “Why can't you heat up the steel reinforcement bars themselves and fuse them to fixed plates?” To begin with, the Equipment Business Division was set up to take requests, complaints, and opinions from customers, equipping induction heating technology, not to sell construction material. However, the sales representative who filled this inquiry, Norihiko Terada―perhaps relying on his intuition as well as sales experience ―told the customer that “We do not sell equipment.

You should rely on us first as a processing business,” when Terada was subsequently asked by his supervisor in an accusatory manner why he had not accepted the job, he took that frustration directly to the development staff and asked them what they could do.

A meeting with a “god” who ended up inventing revolutionary technologies

In the engineering division of the Kawasaki Works facility was a man named Tsukasa Maenosono, who was sometimes called the “god of heating.” Norihiko Terada (see above) talked about his idea of a method for connecting fixed steel plates to rebars, an idea he had gotten earlier after an inquiry from a general construction contracting firm.

Maenosono immediately took it upon himself to respond to Terada's inquiry and began thinking about how best to do it. Seeing the simple processes involved, namely the plates and rebars together, Maenosono offered that there might be a more efficient way of it. He suggested that rather than using the plate as the “hook,” it would be better to just heat up the end of the rebar and hammer it flat instead. With this suggestion he invented the T-head construction method. This was a truly revolutionary technical development, one that no other company had produced up till then.

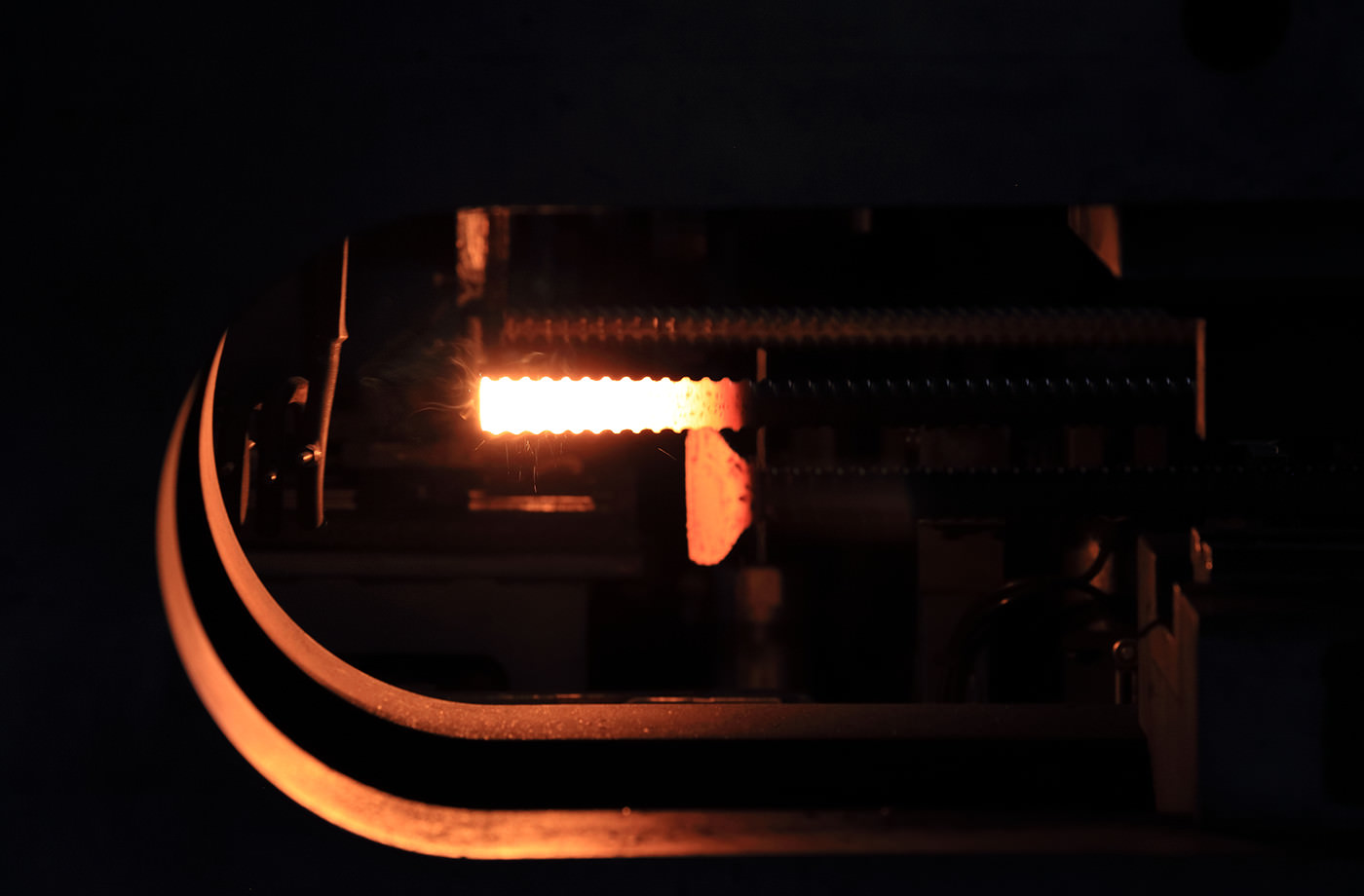

At first our engineers considered producing T-head re-bar using the traditional mold-casting method, where highly heated steel bar is pushed into a custom built mold. Although this would allow for simple mass production, they realized that making the molds would be very expensive and thus a significant manufacturing hurdle. Instead, Maenosono decided to make use of existing DHF induction heating technology, using induction heating to heat the end of the re-bar before flattening it into shape. After much trial and error he finally came upon the proper temperatures, pressures, and hammering speeds to produce T-head construction method re-bar without using expensive molds. I was fortunate to be able to observe theT-head development process as it happened. It seemed almost divine in its conception and brought about a feeling of excitement that I have not forgotten to this day.

The recent spread of seismic dampening technology for use in high-rise construction

More recently, DHF has expanded its business, propelled in large part by the demand for general construction and public works, especially in tunnel construction. In 2005 our Company received the 4th Infrastructure Technology Development Award from the Ministry of Land, Infrastructure, Transport and Tourism for our expertise in the development of T-head construction technology.

In recent years, there has been a trend to increase the amount of rebar used in construction to improve seismic resistance, a trend which has led to higher costs for materials as well as installation. The use of more rebar to connect pillars and beams has in turn led to an over concentration and overcrowding of rebar, making it difficult to properly pour concrete into the forms and thus increasing the risk of faulty reinforcement. Using DHF's revolutionary T-head steel-bar reinforcement construction method effectively solves these problems. It goes without saying that this reliable sturdiness is easy to install/construct and comes at a relatively low price. This technology is emblematic of our business principle of always being ready to help construction project and customers solve their problems.